Products

- Deck Covering

- Light Primary Deck Covering

- Super Light Primary Deck

- Class A-60 Light Floating

- Class A-60 High Sound Insulation

- DKY-GF Type Class A-60 High

- Class A-60 light fireproof Deck

- Flat Deck Covering Type DKY-5

- ClassA-60 Light composite

- Light Self-Leveling Primary Deck

- Ultralight Self-Leveling Primary

- Ceramic adhesive Type DKY-J1

- Floor tile seam filling agent

- Cement covering Type DKY-S

- Marine-use Assembly Cold

- Integral Cold Storage Unit

- Fittings for refrigerating

- Marine Shading shutter

Contact us

Jingjiang Dakeyuan New Material Engineering Co., Ltd.

Contact:Mr. Yuan

Phone:13809011028

Contact:Mr. Jiang

Phone:13809082860

Tel: 0523-89195899 84240399

Fax:0523-84240299

Email:dky218@vip.163.com

Web:

Adds:No. 8 Xiexin Road, Xieqiao Town, Jingjiang City

Light Primary Deck Covering Type DKY-1

◇ Product Introduction

Because of their low density, strong adhesion with the base surface and high impact resistance, the products are especially suitable for the deck of various vessels, warships and marine engineering ships with the strict requirements fireproof performance of materials.

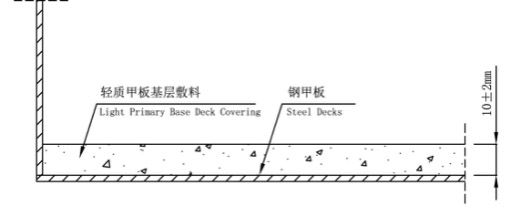

◇ Product Structure Type:

|

Density |

≤1300kg/m3 |

|

Flexural strength |

≥3.5MPa |

|

Compressive strength |

≥8MPa |

|

Initial set time |

≥1h |

|

Final set time |

≤24h |

|

Thermal conductivity |

≤1.2W/m.k |

|

Impact resistance |

No crack or separation |

|

Not easy ignitibility, Smoke & toxicity. |

Accord with IMO.FTPC Part 2,5 |

◇ Packing and Usage

|

Material name |

Packing |

Usage |

|

Emulsion (Component A) |

9.7kg/keg |

0.25 keg/m² |

|

Powder (Component B) |

10kg/bag |

0.5 bag/m² |

|

Filling(Component C) |

19kg/bag |

0.5 bag/m² |

◇ Stirring Method:

△1bag of powder (component B) and 1 bagsfilling (component C) mixed evenly, and then 0.5 barrels of emulsion (component A) gradually added to continue to fully mixing, can be laid after the uniform thick mud. Dressing should not be used when stirring speed mixing machine mixing, stirring rate that is less than or equal to 100 R / min, stirring time is 3-5 minutes. If the use of artificial mixing, the dressing must be mixed evenly.

△ In theory these component A, B and C can spread over an area of 2m² with thickness of 10mm.

◇ Construction Technology:

△ Steel deck must be flatted

△ All the dust, water and oil smudges on the deck should be cleared, and then derusted according to the St2 of CB3230.

△ The stirred mortar of light primary deck covering is spread on the steel deck. A tool of iron plate should be used to press and rub the layer, and make the covering fully bonded with the steel deck.

△ A long wooden ruler should be used to float the covering to the thickness as required. After surface moisture volatilizes, the iron plate should be used again to press and smooth the surface of the layer.

◇ Attentions:

△ At normal temperatures, the setting time is about 18 hours. But as the change of environmental temperature and humidity, the setting time will be a little shorter or longer.

△ The place of storing should be at a cool, ventilated place in avoidance of being exposed to the rain or strong sunshine. It is forbidden to damp the materials.

△ The appropriate temperatures are between 5~30℃. If the environmental temperature is higher or lower than those above mentioned, the necessary measures to cool or warm should be taken.

△ If the components are stirred by hand, or the environmental temperature is too high, the viscosity of deck covering will be higher as well. In this case, clean water can be added properly. But too much water will directly affect the strength of the material.

△ After the laying of covering, the layer must be under necessary conservation, such as spraying setting solution or water. Or its surface is covered with some airtight material.

△ Quality guarantee period is 6 months.