Products

- Deck Covering

- Light Primary Deck Covering

- Super Light Primary Deck

- Class A-60 Light Floating

- Class A-60 High Sound Insulation

- DKY-GF Type Class A-60 High

- Class A-60 light fireproof Deck

- Flat Deck Covering Type DKY-5

- ClassA-60 Light composite

- Light Self-Leveling Primary Deck

- Ultralight Self-Leveling Primary

- Ceramic adhesive Type DKY-J1

- Floor tile seam filling agent

- Cement covering Type DKY-S

- Marine-use Assembly Cold

- Integral Cold Storage Unit

- Fittings for refrigerating

- Marine Shading shutter

Contact us

Jingjiang Dakeyuan New Material Engineering Co., Ltd.

Contact:Mr. Yuan

Phone:13809011028

Contact:Mr. Jiang

Phone:13809082860

Tel: 0523-89195899 84240399

Fax:0523-84240299

Email:dky218@vip.163.com

Web:

Adds:No. 8 Xiexin Road, Xieqiao Town, Jingjiang City

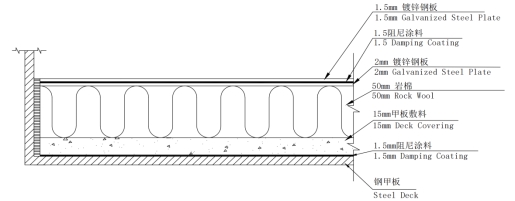

DKY-GF Type Class A-60 High Sound Insulation Floating Floor

◇Product Introduction:

This product has good floating performance ; effectively reduce structural noise and vibration noise ; suitable for ships with high sound insulation requirements.

◇Product Structure Type:

◇Product Specifications:

|

Rock Wool |

Density |

≥140 kg /m3 | |

|

Non-combustibility |

Accord with IMO.FTPC Part 1 | ||

|

Self-Leveling Primary Deck Covering |

Solidified body |

Density |

≤1200 kg /m3 |

|

Flexural strength |

≥5M Pa | ||

|

Compressive strength |

≥15MPa | ||

|

Initial set time |

≥50min | ||

|

Final set time |

≤6h | ||

|

Thermal conductivity |

≤1.2 W /m .k | ||

|

Mobility |

≥130mm | ||

|

Impact resistance |

No crack or separation | ||

|

Non-combustibility |

Accord with IMO.FTPC Part 1 | ||

|

D a m p i n g

m a t e r i a l |

Drying time |

Surface is dry≤6h ; Actual drying≤12h | |

|

Shore hardness |

20-40 | ||

|

Density |

1. 1±0. 1g/c m³ | ||

|

Adhesion |

≥2.5 MPa | ||

|

Composite loss factor |

≥0.1 | ||

|

Ensemble |

Sound Insulation Index |

≥56dB | |

◇ Packing and Usage

|

Material name |

Material specification |

Laying amount |

|

Damping material |

Group A: 2.1 Kg (4 liter iron barrel) |

0.55 groups / ㎡ / 1.5mm |

|

Group B: 0.9 Kg (plastic bag) | ||

|

Self-leveling base

application material |

Powder lot |

1 bag / ㎡ |

|

Surfactant |

0.1kg / ㎡ | |

|

Galvanized sheet |

1250 × 1250 × 1.5mm |

1.28 pieces / ㎡ |

|

Galvanized sheet |

1250 × 1250 ×2mm |

0.64 pieces / ㎡ |

|

Rock wool board |

1200 ×600×50mm

Capacity: 140kg / m³ |

1.39 pieces / ㎡ |

◇Construction Technology:

△All steel decks shall be clean and free of grease, dust or other contaminants that may reduce adhesion. All steel decks shall be protected against rust and painted with rust-proof primer ;

△The damping coating is mixed evenly according to components A

and B, evenly painted on the surface of the steel deck with a scraper, and flattened with a roller. The construction thickness is 1.5mm.

△Evenly evenly with quartz sand, about 0.5kg per square meter

△Damping curing (about 12 hours), the construction of leveling base deck dressing, using the mixer mixing leveling base deck dressing mixing and water mixing ratio is : 1 bag with 4.2kg, after mixing the dressing dumped on the steel deck, using tools(defrestered drum, scraper) to remove bubbles, do the thickness required for deck dressing (15mm).

△After 24 hours of deck dressing curing, the 50mm thick rock wool is laid, and the rock wool and rock wool should be misstitched and closely stitched together.

△After the completion of laying the rock wool, two layers of galvanized steel plate are pre-laid first. The specification of the bottom galvanized steel plate is 2.0 × 1250 × 1250, and the specification of the surface galvanized steel plate is 1.5 × 1250 × 1250. The bottom plate seam can be filled when applying the damping layer), there should be 2-3mm gap between the surface steel plate and the steel plate, and the upper and lower steel plates should be stitched. Keep 8~10mm gap between the steel wall and steel deck, and can not be overlapped. Open the galvanized steel sheet and brush the damping coating on the surface of the first galvanized steel sheet with a scraper. Before the damping is not solidified, lay the galvanized steel sheet (placed according to the pre-laying position), and finally fix with self-tapping screws. Each steel plate is fixed with about 5 screws (one in each of four corners and one in the middle).

△For 12 hours after the composite structure is laid, the excess damping coating can be removed.

◇ Attentions:

△ When laying rock wool, try to keep the seam close.

△ When laying the galvanized sheet plate, try to keep the wrong seam stitching.

△ Raw materials should be placed and stirred in a cool and ventilated place to avoid sun exposure and rain, and strictly subject to moisture.

△When the appropriate construction temperature is between 5 and 30℃, and the ambient temperature is higher or lower than the above temperature, necessary cooling or insulation measures should be taken.

△ The product shelf life is 6 months.