Products

- Deck Covering

- Light Primary Deck Covering

- Super Light Primary Deck

- Class A-60 Light Floating

- Class A-60 High Sound Insulation

- DKY-GF Type Class A-60 High

- Class A-60 light fireproof Deck

- Flat Deck Covering Type DKY-5

- ClassA-60 Light composite

- Light Self-Leveling Primary Deck

- Ultralight Self-Leveling Primary

- Ceramic adhesive Type DKY-J1

- Floor tile seam filling agent

- Cement covering Type DKY-S

- Marine-use Assembly Cold

- Integral Cold Storage Unit

- Fittings for refrigerating

- Marine Shading shutter

Contact us

Jingjiang Dakeyuan New Material Engineering Co., Ltd.

Contact:Mr. Yuan

Phone:13809011028

Contact:Mr. Jiang

Phone:13809082860

Tel: 0523-89195899 84240399

Fax:0523-84240299

Email:dky218@vip.163.com

Web:

Adds:No. 8 Xiexin Road, Xieqiao Town, Jingjiang City

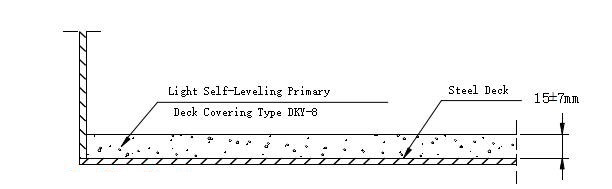

Light Self-Leveling Primary Deck Covering Type DKY-8

◇ Product Introduction

It is formulated by mixing ultra-early strength special cement, water-based quick-setting binder, high-strength wear-resistant materials and special additives. It has good flow performance, rapid curing molding, strong adhesion to the substrate, and smooth surface after molding. It is used as an automatic leveling dressing on ships, offshore platforms and various steel decks covering.

◇ Product Structure Type:

◇ Product Specifications:

|

Density |

≤1200kg/m3 |

|

Flexural strength |

≥5MPa |

|

Compressive strength |

≥8MPa |

|

Initial set time |

≥50min |

|

Final set time |

≤6h |

|

Thermal conductivity |

≤1.2W/m.k |

|

Fluidity |

φ≥130min |

|

Impact resistance |

No crack or separation |

|

Low spread flame, smoke and toxicity. |

Accord with IMO.FTPC Part 2,5 |

◇ Packing and Usage

|

Material name |

Packing |

Usage(13mm) |

|

Powder |

18kg/bag |

1 bag/m² |

|

Surfactants |

5 kg/keg |

50m² |

◇ Stirring Method:

△The surfactant is evenly applied to the base surface, and the self-leveling can only be applied after the primer is fully dry, and the time is more than 2 hours, and the maximum is 24 hours.

△Self-leveling construction: pour 1 self-leveling package into the barrel and add about 4.2kg of clean water for full stirring and mixing until a fine and non-agglomerated slurry fluid is produced, the stirring time is about 1.5-5 minutes, and it is automatically leveled after pouring into the base surface, and the scraper or defoaming roller is used to remove air bubbles and further control the construction thickness and flatness.

△One set can lay 10mm thickness gauge 1.3 square meter.

◇ Construction Technology:

△The steel deck must be kept flat on the base, and the flatness of the steel deck needs to be between ±2mm within 2m before the self-leveling dressing can be applied, otherwise the amount of dressing will be greatly different and need to be supplemented.

△Steel decks that are not epoxy primed shall be free of dust, oil and moisture, and shall be derusted according to the St2 rust removal standard in CB 3230; Steel decks with epoxy primers must be cleaned to be dust-free, oil-free and moisture-free.

△The hull should be leveled as much as possible, and the inclination of the boat should be controlled≤1º, which meets the construction requirements of self-leveling dressings.

△The boundary of the construction area is separated by self-adhesive isolation material to avoid self-leveling flowing into other areas in the later stage, and strive to evenly and comprehensively cover the interface layer during construction.

△Ventilation and direct sunlight must be prohibited for 3-5 hours when applying deck dressings.

△During self-leveling, the amount of material is controlled in time to reach the required thickness, which can be adjusted using scrapers or defoaming rollers.

◇ Attentions:

△ At normal temperatures, the setting time is about 6 hours. But as the change of environmental temperature and humidity, the setting time will be a little shorter or longer.

△ The place of storing should be at a cool, ventilated place in avoidance of being exposed to the rain or strong sunshine. It is forbidden to damp the materials.

△ The appropriate temperatures are between 5~30℃. If the environmental temperature is higher or lower than those above mentioned, the necessary measures to cool or warm should be taken.

△ Quality guarantee period is 6 months.