Products

- Deck Covering

- Light Primary Deck Covering

- Super Light Primary Deck

- Class A-60 Light Floating

- Class A-60 High Sound Insulation

- DKY-GF Type Class A-60 High

- Class A-60 light fireproof Deck

- Flat Deck Covering Type DKY-5

- ClassA-60 Light composite

- Light Self-Leveling Primary Deck

- Ultralight Self-Leveling Primary

- Ceramic adhesive Type DKY-J1

- Floor tile seam filling agent

- Cement covering Type DKY-S

- Marine-use Assembly Cold

- Integral Cold Storage Unit

- Fittings for refrigerating

- Marine Shading shutter

Contact us

Jingjiang Dakeyuan New Material Engineering Co., Ltd.

Contact:Mr. Yuan

Phone:13809011028

Contact:Mr. Jiang

Phone:13809082860

Tel: 0523-89195899 84240399

Fax:0523-84240299

Email:dky218@vip.163.com

Web:

Adds:No. 8 Xiexin Road, Xieqiao Town, Jingjiang City

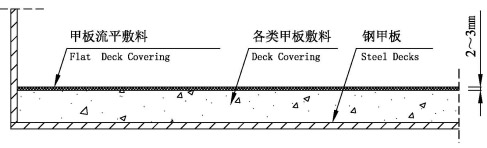

Flat Deck Covering Type DKY-5

◇ Product Introduction

The product possesses very strong adhesion with the base layer covering, and very strong wear resistance. So this kind of flat deck covering is suitable for use on all surfaces of various ordinary deck covering.

◇ Product Structure Type:

◇ Product Specifications:

|

Density |

≤1800kg/m3 |

|

Flexural strength |

≥3.5MPa |

|

Compressive strength |

≥15MPa |

|

Initial set time |

≥1h |

|

Final set time |

≤8h |

|

Impact resistance |

No crack or separation |

|

Vibration test |

No crack or separation |

|

Fluidity |

250mm≤Ф≤300mm |

|

Low smoke spread, smoke and toxicity |

Accord with IMO.FTPC Part 2,5 |

◇ Packing and Usage

|

Material name |

Packing |

Usage |

|

Latex (Component A) |

4.8kg/keg |

0.2 keg/m² |

|

Powder (Component B) |

17kg/bag |

0.2 bag/m² |

◇ Stirring Method:

△ 1 keg of latex (Component A) is poured into a clean container, and then 1 bag of powder (Component B) is also poured slowly into while being mixed by a stirrer. When the mixture becomes floating even liquid and setting 2~4 minutes later, it can be spread after being stirred again.

△ Each set can spread an area of 5m² with 2mm thickness.

◇ Construction Technology:

△ All the dusts and smudges on the deck surface should be cleared thoroughly.

△ Before the work of laying flat covering begins, some necessary pretreatment for seriously uneven deck covering should be carried out. An angle grinder is to be used to grind off obviously raised part; while latex cement used to patch obviously low-lying area.

△ Because of the strong absorption of water by the base layer, setting solution or water is necessary to wet the base layer before the laying work begins. But the operation cannot begin till the water on the surface is absorbed by the layer.

△ The flat deck covering stirred is poured onto the area needed laying, and then spread and smoothed with iron plate, The thickness of the layer is controlled between 2~3mm. After natural floating, the layer will have a flat and smooth surface.

◇ Attentions:

△ The self-leveling deck covering is a type of quick curing and hardening material. Therefore, the stirring and laying work must be finished in 20 minutes. So it is proposed to stir this type of covering within the laying site.

△ In order to achieve a more desirable effect of laying, it is much better to use an ultra long dentate scraping plate.

△ Coagulant powder used in the self-leveling deck covering is not applicable for general Portland cement. So it cannot be mixed with other cement.

△ The suitable temperatures for construction are between 5~30℃. If the environmental temperature is higher or lower than those above mentioned, the necessary measures to cool or warm should be taken.

△ This type of deck covering is not proper to be stirred by hand. It is suitable to use a low speed stirrer to avoid producing too many bubbles.

△ After laying of flat deck covering, the layer should be conserved for 12~24 hours according to the environmental temperatures. The next process cannot begin till the end of the conservation.

△ Materials should be stored in a cool dry place. It is forbidden to damp them.

△ Quality guarantee period is 6 months.