Products

- Deck Covering

- Light Primary Deck Covering

- Super Light Primary Deck

- Class A-60 Light Floating

- Class A-60 High Sound Insulation

- DKY-GF Type Class A-60 High

- Class A-60 light fireproof Deck

- Flat Deck Covering Type DKY-5

- ClassA-60 Light composite

- Light Self-Leveling Primary Deck

- Ultralight Self-Leveling Primary

- Ceramic adhesive Type DKY-J1

- Floor tile seam filling agent

- Cement covering Type DKY-S

- Marine-use Assembly Cold

- Integral Cold Storage Unit

- Fittings for refrigerating

- Marine Shading shutter

Contact us

Jingjiang Dakeyuan New Material Engineering Co., Ltd.

Contact:Mr. Yuan

Phone:13809011028

Contact:Mr. Jiang

Phone:13809082860

Tel: 0523-89195899 84240399

Fax:0523-84240299

Email:dky218@vip.163.com

Web:

Adds:No. 8 Xiexin Road, Xieqiao Town, Jingjiang City

Class A-60 High Sound Insulation Floating Floor Type DKY-3H

◇ Product Introduction

Being a high sound insulation floating type, this product possesses good sound insulation, noise reduction, shock absorption and fire resistance. So it is suitable for the floor in living compartments and control rooms adjacent to machinery spaces on the class A-60 vessel’s deck.

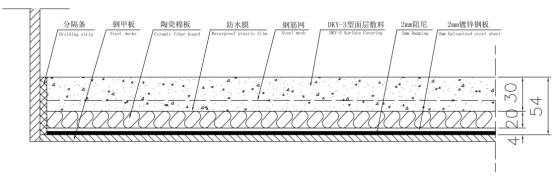

◇ Product Structure Type:

◇ Product Specifications:

|

Base Material |

Ceramic Fiber Board |

Density |

≥170 kg/m3 |

|

Non-combustibility |

Accord with IMO.FTPC Part 1 | ||

|

Surface Covering |

Solidified body |

Density |

≤1500 kg/m3 |

|

Flexural strength |

≥4MPa | ||

|

Compressive strength |

≥15MPa | ||

|

Initial set time |

≥1 h | ||

|

Final set time |

≤24 h | ||

|

Thermal conductivity |

≤1.2 W/m.k | ||

|

Impact resistance |

No crack or separation | ||

|

Vibration test |

No crack or separation | ||

|

Noncombustible |

Accord with IMO.FTPC Part 1 | ||

|

Overall |

Fire resistance |

Accord with IMO.FTPC Part 3 | |

|

Overall |

Sound Insulation Index |

≥55dB | |

◇ Packing and Usage

|

Material Name |

Packing |

Usage |

|

Powder (Component A) |

18.5Kg/ bag |

1 bag/m² |

|

Filling(Component B) |

21.8Kg/ bag |

1 bag/m² |

|

PE Waterproof film |

width 4000mm |

0.25m/ m² |

|

Steel mesh |

Ф3,1100×2000mm,Aperture 50×50m |

0.5 unit/m² |

|

Ceramic fiber board |

1000×500×20mm |

2 unit/m² |

|

Damping coating |

Component A: 2.1kg/barrel |

0.55 barrel/m² |

|

Component B: 0.9kg/ bag |

0.55 bag/m² | |

|

Galvanized steel |

1.5625m²/unit(1250×1250mm) |

0.64 unit/m² |

◇ Construction Technology:

△ Steel deck must be flatted

△ All the dust, water and oil smudges on the deck should be cleared, and then derusted according to the St2 of CB3230.

△ The deck surface should be coated with anti rust paint 1~2 times,and apply the 2mm damping coating after curing..

△ On the plate laying 20mm thick ceramic cotton board, seam closely.

△ A waterproof film is laid on the ceramic cotton board, and the lap width is not less than 100mm.

△ Steel mesh is laid out on the ceramic fiber board. The overlap width should not be less than 100mm, And the overlaps must be fastened with galvanized iron wire.

△ The covering mortar stirred is spread on the film. A long wooden ruler should be used. While the layer is being leveled, the steel mesh must be lifted up 5~10mm. And then the layer should be pressed with iron plate into a dense structure. The layer thickness is ≥ 30mm, and its surface should be smoothed.

◇ Attentions:

△Floating deck covering is a kind of flexible coupling. So the floating deck covering cannot be put to the next process until it is set thoroughly. At normal temperatures, the setting time is about 36 hours. But as the change of environmental temperature and humidity, the setting time will be a little shorter or longer.

△ The place of storing and mixing of the components should be at a cool, ventilated place in avoidance of being exposed to the rain or strong sunshine. It is forbidden to damp the material.

△ The appropriate temperatures are between 5~30℃. If the environmental temperature is higher or lower than those above mentioned, the necessary measures to cool or warm should be taken.

△ After the laying of covering, the layer must be under necessary conservation, such as spraying setting solution or water. Or its surface is covered with some airtight material.

△ Quality guarantee period is 6 months.